Bangkok, 16 September 2024 – SCG has unveiled its “Future Forward” plan to accelerate business adaptation, strengthen resilience, increase agility, and reduce carbon emissions in line with the Inclusive Green Growth purpose to build long-term competitiveness. This comes in response to prolonged fluctuations in the petrochemical cycle. SCG is preparing to expand options for petrochemical raw materials in Vietnam’s Long Son Petrochemicals (LSP) using ethane gas, while also promoting Low Carbon Cement exports. SCG seeks to seize opportunities arising from policies supporting green innovation, leveraging technology to enhance sustainable and smart living, and expanding the clean energy business across ASEAN. These efforts aim to create a new S-curve, with a strong push for the “Saraburi Sandbox” project to foster low-carbon economic growth.

Thammasak Sethaudom, President & CEO of SCG, said that the current global situation and the future outlook over the next 2-5 years will be marked by increased volatility. Challenges may arise from a slower-than-expected recovery in the global economy and trade, geopolitical risks, and new rules and opportunities stemming from environmental trends. All SCG businesses are moving forward with strategies that align with these dynamics while also reducing carbon dioxide emissions in line with the Inclusive Green Growth approach to ensure long-term competitiveness.

For SCG Chemicals, which currently accounts for 39% of SCG’s total revenue, the company is accelerating its efforts to enhance competitiveness in response to the continued global petrochemical industry downturn. Additionally, crude oil prices remain volatile, contributing to high raw material costs. In response, the company is implementing plans to increase the operational flexibility of the Long Son Petrochemicals (LSP) project by expanding the range of raw materials used in production. This strategy will allow for better cost management in line with market conditions and help mitigate the impact of raw material price fluctuations. The company plans to increase the proportion of ethane gas as a raw material, alongside the current use of naphtha and propane, as the average price of ethane has been approximately 40% lower than that of naphtha and propane over the past three years. Furthermore, the increased use of ethane will contribute to reducing carbon dioxide emissions and minimizing the production of by-products.

This strengthening effort builds on the core strengths of LSP, which was designed to accommodate gas-based raw materials. The site is equipped with a central utility system, ready for the installation of ethane gas storage tanks and pipelines. Construction is expected to be completed within 3 years. Once operational, LSP will produce olefins and polyolefins, such as polyethylene and polypropylene, to meet the high demand for essential consumer goods in the Vietnamese market. This will be achieved under efficient cost management while prioritizing safety and environmental friendliness. Commercial operations at LSP are scheduled to commence in October 2024.

Additionally, LSP is prepared to support the future production of SCGC GREEN POLYMERTM, a green plastic innovation that delivers high added value and continues to experience strong growth in line with global environmental trends. This innovation will help improve the quality of life for people in Vietnam and across the ASEAN region.

In the cement and building-related businesses, SCG Cement and Green Solutions is focused on boosting competitiveness to prepare for the implementation of carbon tax measures that are being enforced in many countries. The business has proactively reduced carbon dioxide emissions throughout its entire operations in line with industry trends, while also capitalizing on growth opportunities driven by policies supporting the use of Low Carbon Cement in public and private sector projects. To date, SCG has successfully exported over 1 million tons of Low Carbon Cement to the United States, and it is expanding exports to new markets in ASEAN, Australia, and Canada. The company is advancing its research and development (R&D) efforts, currently working on the development of third-generation Low Carbon Cement. This new technology allows for an increased proportion of clinker substitution in the production process, resulting in a 40-50% reduction in carbon dioxide emissions compared to conventional cement. These efforts aim to meet the growing demand for Low Carbon Cement, while also accelerating the expansion of its Low Carbon Cement production capacity in southern Vietnam, a high-potential market that could serve as a future export hub.

SCG Smart Living’s direction for the next 3-5 years will focus on developing more low-carbon products in its core construction materials category to meet the growing demand in the green market. The emphasis will be on reducing carbon emissions while maintaining attractive design and enhanced durability. Additionally, there are plans to incorporate artificial intelligence (AI) into product design, enabling faster production and customization according to customer needs. At the same time, the company will improve its manufacturing processes by increasing the use of robotics to reduce waste and manage costs to remain competitive with new market players, such as China. The company is also preparing to expand its construction materials market into high-growth regions like India and the Middle East. Furthermore, SCG aims to increase the proportion of system-based products that address the demand for faster construction and better performance, particularly lightweight wall systems that are easy to install, offer heat and sound insulation, and roofing systems with various designs that can be customized to suit different housing styles and needs. These systems will also feature energy-saving and heat-resistant functions.

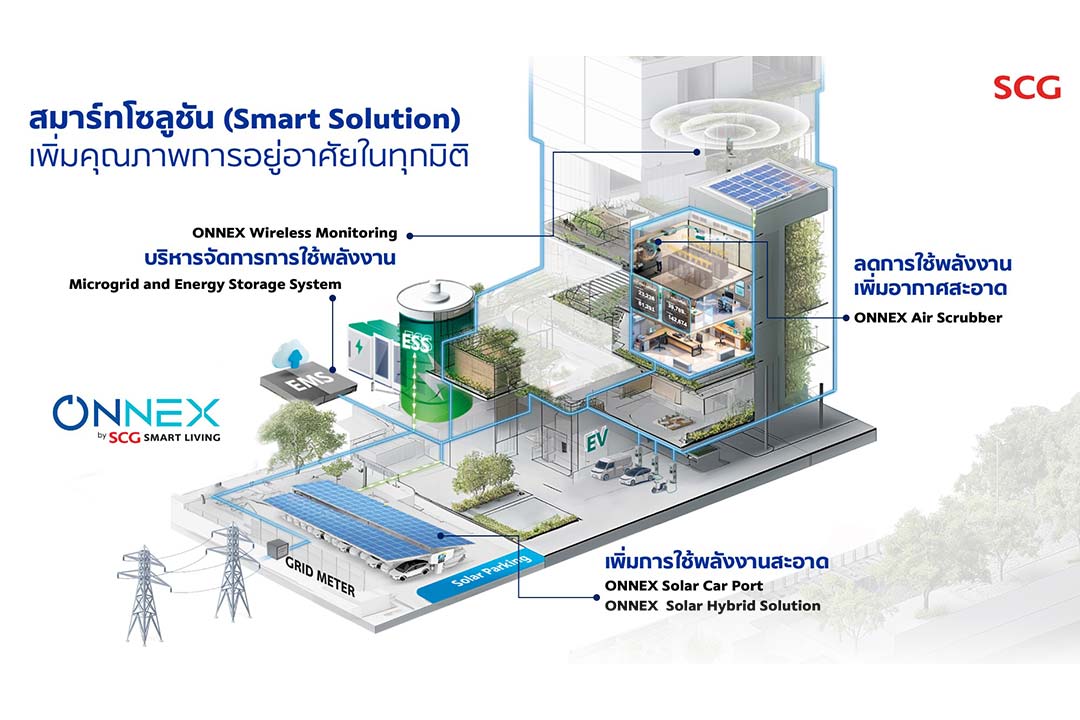

SCG is advancing its smart solutions under the ‘New S-Curve’ initiative through the ‘ONNEX’ brand, combining SCG’s expertise with cutting-edge technology to enhance all aspects of living. This includes energy-saving systems like the ‘Air Scrubber’ for air purification and ‘Solar Hybrid Solutions’ for clean energy. The ‘Bi-on’ system monitors air quality in homes and buildings. In the future, SCG will introduce solutions tailored to elderly care, addressing the aging population trend. The company is also preparing to integrate all ONNEX solutions into a single platform, managed through the digital operating system ‘Trinity,’ to provide greater convenience for users.

SCG Distribution and Retail is utilizing digital platforms and AI to enhance its distribution system, making it more convenient for customers and partners to access products. This approach reduces inventory holding time and allows for better forecasting of future product demand, helping businesses remain competitive in a rapidly changing market. For instance, ‘the Prompt Plus application,’ designed for wholesale operations, helps analyze and recommend products based on personalized needs, optimizing inventory management for distributors and small retailers. At the same time, the company is expanding green construction and housing solutions into high-growth markets. This includes offerings such as ‘CPAC Ready Mixed Concrete’ and ‘CPAC 3D Printing Solution,’ which improve construction accuracy and reduce on-site waste. These innovations are being introduced in Saudi Arabia.

SCG Cleanergy, part of the New S-Curve business, is expanding into ASEAN markets, including Vietnam, Indonesia, and the Philippines, with the goal of achieving 3,500 megawatts of renewable energy production by 2030. With its strengths in innovation and end-to-end clean energy solutions, SCG Cleanergy offers world-class systems for energy storage system and electricity distribution through its ‘Smart Micro Grid’ clean energy platform. Additionally, the company is constructing the world’s first ‘Heat Battery’ unit for clean energy storage, specifically designed for the cement industry, at SCG’s cement plant in Saraburi Province. SCG Cleanergy is further reinforcing its capabilities through investments in cutting-edge technology companies, including one that develops ‘Tandem Perovskite’ solar cells. This company holds one of the top global rankings for patents in this field. The technology helps produce solar cells with up to 30% efficiency, making clean energy more accessible to the industrial sector.

In this forward-looking plan, SCG is implementing strict financial measures, carefully considering investments under an annual investment budget of 40,000 million baht. The company is aiming to reduce working capital in its business by 10-15% through improved operational efficiency. SCG will focus on high-potential businesses while closing non-profitable ones, reallocating resources and personnel to areas with growth opportunities. H1/2024, the company holds 78,907 million baht in cash reserves.

Thammasak added that regarding the company’s strategy for future business expansion that SCG is accelerating its technological capabilities by integrating AI to drive every aspect of the business. The company is supporting all employees in working collaboratively with AI, ensuring a deep understanding of its practical application and scaling these efforts for long-term business potential. Several projects are already underway or in the development phase, such as using AI to offer personalized home shopping experiences for customers and utilizing AI for machine monitoring and maintenance to enhance operational accuracy.

Additionally, SCG, in collaboration with the public sector, private sector, and civil society, is driving the “Saraburi Sandbox,” Thailand’s first low-carbon model city, aimed at reducing greenhouse gas emissions through five key initiatives: 1) transitioning to clean energy by leveraging the area’s potential and grid modernization, 2) promoting green industries that produce green and low-carbon products, 3) creating added value from waste, 4) implementing alternating wet and dry rice farming to reduce water use and carbon emissions, and 5) increasing green spaces, promoting eco-tourism, and seeking international green funding to support the development of low-carbon innovations, such as Carbon Capture Utilization and Storage (CCUS) technology, to foster low-carbon economic growth. The goal is to reduce Saraburi Province’s greenhouse gas emissions by 5 million tons of carbon dioxide equivalent by 2030, supporting the cement industry’s target of achieving net-zero greenhouse gas emissions by 2050.

“SCG closely monitors all aspects of both Thai and global situations, including the economy, geopolitics, society, and the environment, as these factors are interconnected and have mutual impacts. At the same time, SCG analyzes these factors in advance, develops plans that are suitable for each moment, and adapts swiftly to ensure business continuity and stability. In addition to building strong competitiveness in the short, medium, and long terms, SCG maintains financial stability while expanding into new, high-potential businesses, responding to every opportunity and challenge as they continuously evolve,” the President and CEO concluded.

Published on: Sep 16, 2024