A President at the Cement-Building Materials Business of one Southeast Asia’s leading conglomerates, SCG (formerly known as the Siam Cement Group), Nithi Patarachoke recently spoke with Brunswick about leadership, sustainability commitments, and key trends set to shape Southeast Asia.

Established in 1913, SCG is the largest and oldest cement and building material company in Southeast Asia, operating today in over twenty markets around the world. Headquartered in Thailand, SCG is comprised of three core businesses: cement-building materials, chemicals and packaging.

Leading the Cement-Building Materials Business as President is Nithi Patarachoke, a role he has held since 2018. That position places Patarachoke at the helm of the business which generates a high amount of SCG’s revenue—and also its emissions. The former means that the cement-building materials business has an important role to play in SCG’s aggressive investment strategy in ASEAN countries, particularly Vietnam, while the latter means that the business has a key role to play in meeting SCG’s ambitious sustainability targets, including ones the company has set for 2030 and 2050.

In a wide-ranging conversation with Brunswick’s Dararin Choomsai Na Ayuthaya, Patarachoke reflected on what it will take to reduce greenhouse gas emissions in a hard-to-abate sector like cement—an industry responsible for almost 8% of global emissions. “We needed to disrupt ourselves before being disrupted by rapid changes,” he says.

Many ASEAN countries successfully managed the pandemic early on, but have since been hit hard by variants. How has that shift affected daily life in Thailand—and how has it affected SCG more broadly?

The COVID-19 pandemic has turned the lifestyles and behaviors of consumers upside down. Such a turn of events, of course, drastically disrupted various business sectors not only in Thailand but also across ASEAN countries, especially tourism, air transportation, automobile, real estate, and export sectors.

The good news is the increasing vaccination rate in ASEAN countries could improve economic growth momentum in 2022. However, a global recession is the apparent headwind and we therefore would not expect a robust recovery in the short term. Industries like household consumer products, financial services, and information technology are likely to enjoy a healthier recovery than others.

For SCG, we encountered supply chain disruptions and rising costs for energy as well as raw materials. These were the challenges we needed to cope with to sustain our production efficiency.

Was the Cement-Building Materials Business affected by the pandemic in ways that SCG’s other business units were not?

The Cement-Building Materials Business was affected mainly by the lockdowns in major cities that led to the shutdown of construction sites, resulting in lower sales of key construction materials such as cement, ready-mixed concrete, and ceramic tiles. On the consumer side, changing lifestyles and financial concerns saw many people delay buying new houses or condominium units.

Yet the home renovation segment saw significant growth as people spent more time at home and working from home. The health and hygiene sector also enjoyed growth as the pandemic made people much more conscious about their wellbeing. We have had to adapt and expedite our innovation to serve the surging market needs.

How does Cement-Building Materials Business plan to “recover better”?

We developed several strategies. We upgraded our digital technologies, for instance. Our customers’ preferences have shifted when searching for building materials. Before the pandemic, they would visit the showroom to see the products; now many prefer to browse online and do their own price and design comparisons before experiencing the real products at physical store. A lot of consumers are now opting for an online home-building consultation instead of coming to our physical store.

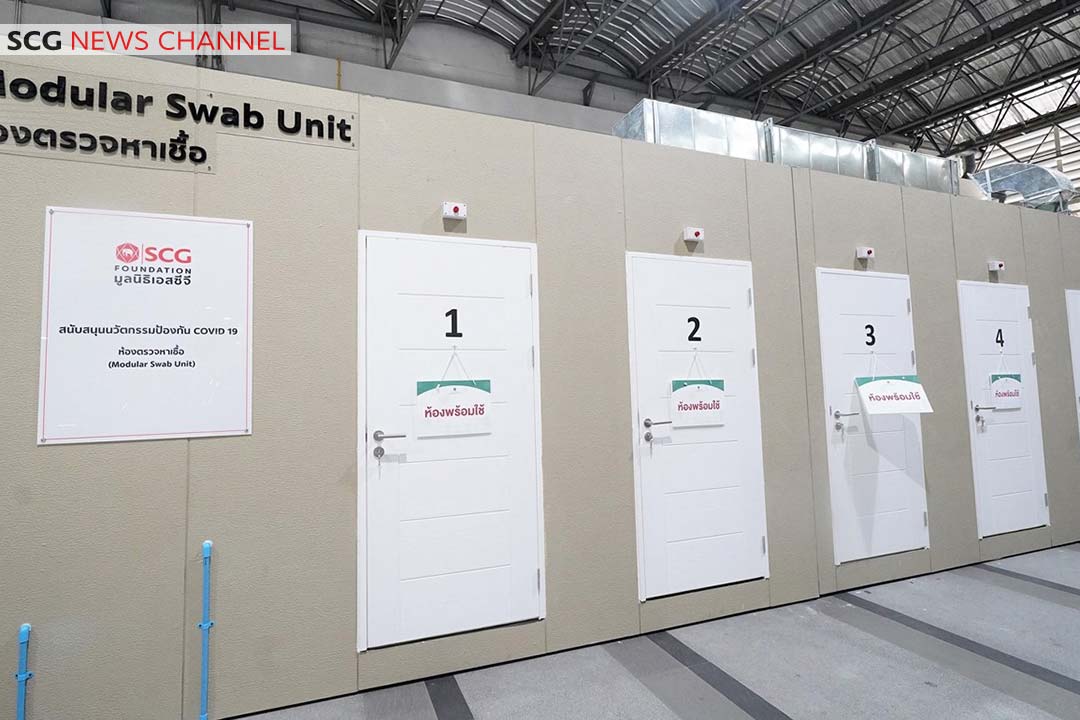

We’re also using our construction experience to help society “recover better” too. SCG has developed solutions for such as ICU modular screening and swab units, which make it safe for both medical professionals and patients to test for COVID-19. These units can be installed in as little as two days, and have already been rolled out in Thailand and other ASEAN countries such as Vietnam, Cambodia, and Indonesia to support the pandemic relief efforts.

What actions are you taking to lower emissions in your operations and become climate-resilient? And what results have you achieved so far?

SCG set its greenhouse gas mitigation targets in line with the Paris Agreement’s goals of limiting global warming to well below 2 degrees Celsius while striving to limit the increase to 1.5 degrees Celsius. We are committed to reduce greenhouse gas emission by 20% within 2030 and achieve net zero emissions by 2050, and have set our annual reduction targets in line with Science Based Targets initiative.

We aim to increase our low carbon-footprint products and use alternative fuels—like Refuse Derived Fuel, which is produced by various types of waste—to replace fossil fuels. We’re also working to improve or modify processes and equipment to make them more energy efficient. We also engage in reforestation and rehabilitation of terrestrial forest, mangroves, and seagrass as carbon sinks—SCG worked in partnership with public agencies and communities to plant more than 176,000 trees in the year 2020 alone and plans to plant more trees to help absorb carbon dioxide.

At the same time, we’re raising awareness on climate resilience among employees and our stakeholders. One major project focuses on optimizing water utilization from upstream, midstream to downstream. And solar power is another one of our key achievements. SCG’s 18 solar energy projects have saved more than 11 million kilowatt hours per year and reduced GHG emissions by over 6,700 CO2 tons per year.

Reducing greenhouse gas emissions is hugely challenging for hard-to-abate sectors like cement. What needs to change—policies, technology—for SCG to fulfill its sustainability commitment?

Disruption was already lurking around the corner before COVID, but it has dramatically accelerated. We needed to disrupt ourselves before being disrupted by rapid changes.

We have invested in research and development and have successfully introduced SCG Hybrid Cement, which is low carbon cement, to the market. The new formula cement reduces CO2 emissions in the production process by at least 50 kilograms per ton of cement, approximately 600,000 tons of CO2 reduction annually.

In addition, we aimed to secure more alternative and renewable energy to substitute fossil fuel. Key examples are solar energy from solar farm and solar floating projects, waste-heat generated from cement manufacturing process, and energy pellet produced from agricultural waste.

Are you working with any peers and or partners to create broader change?

We are. Through the Circular Economy in Construction Industry (CECI), we have partnered with various major companies in the construction sector in Thailand to reduce waste and better re-use materials across the industry. We also joined the Global Cement and Concrete Association (GCCA) to share practices, study, and develop innovation to control and minimize GHG emissions in the cement and concrete industry.

What trends are driving the building materials market in Thailand and the Southeast Asian region more broadly? How difficult is it to adapt to these trends during a pandemic?

“Green” is definitely the trend for most, if not all, industries, and building materials is no exception. Consumers are more aware about the environment, greenhouse gas emissions, and natural resource consumption. SCG sees “green” as not just a trend, but a business mandate. We have green operating practices, green construction technologies on our and customers’ end, green logistics to deliver our products to customers, and green products offered as better choices for consumers and the planet.

Energy saving is also gaining its momentum. More consumers are looking for building materials that help reduce energy consumption in their homes and buildings. Solar roofs, for instance, solution has seen higher demands in recent years, since people spend more time at home. Interest in insulation is also growing.

The “health and hygiene” trend also peaked during the pandemic. You can see this in new hygienic building materials like ceramic tiles, which minimize bacteria culture, and touchless sanitary ware. This is reinforced by broader demographic trends—especially aging societies—in ASEAN countries, which further drives the need for hygienic, convenient functions for the elderly.

SCG has been expanding rapidly in ASEAN. What opportunities do you see in these markets, and do you intend to keep expanding?

Most ASEAN countries are located in areas prone to natural disasters, which global warming seems set to exacerbate. Quality building materials and products can help make people, and their properties, safer. Moreover, these countries are developing strongly, especially their infrastructures. New commercial buildings and new house projects are also booming in recent years. We constantly monitor emerging opportunities.

Switching gears—what’s the best piece of advice you’ve gotten on being a leader?

Be a role model for others; lead by example.

Also, make sure you’re leading with empathy and understanding. Listen; be open to other views and suggestions. Always be available and ready to listen—there’s a lot you can learn from your teams, unless you think you already know it all.

Has the pandemic changed your perspective on leadership?

Not really. The pandemic reaffirmed my view that it’s not any single leader who ensures success of any organization, but that success stems from open innovation and teamwork.

Brunswick Review The Leadership Issue

https://www.brunswickgroup.com/scg-president-interview-southeast-asia-i20519/

Published on: Jan 19, 2022

ดาวน์โหลดข่าว

ดาวน์โหลดข่าว